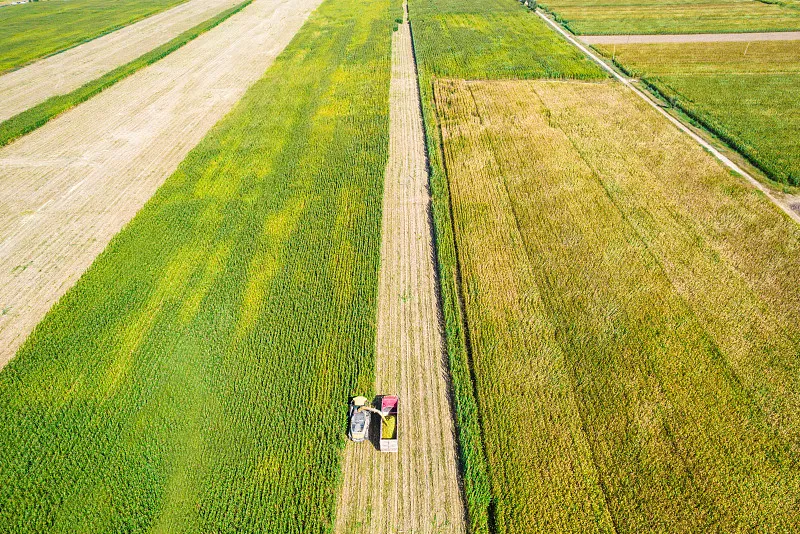

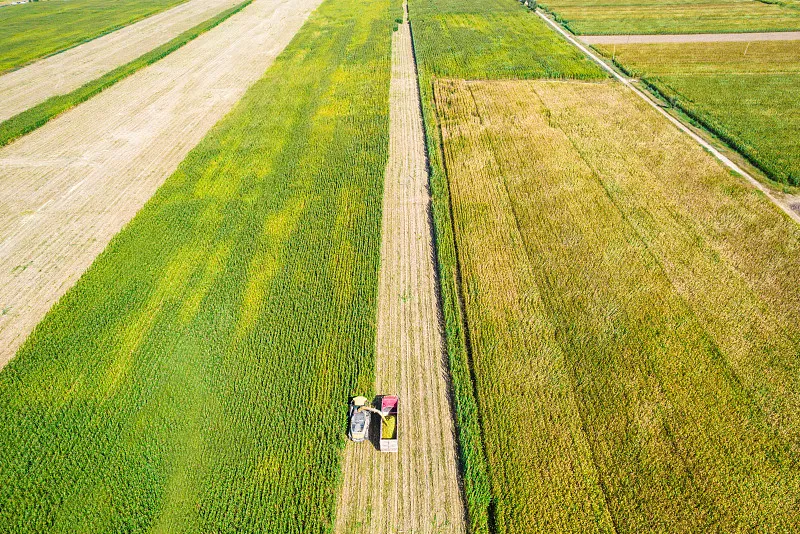

Welcome to the intelligent prediction platform for corn silage fermentation quality. In anaerobic fermentation, quality is comprehensively shaped by raw material characteristics, process parameters, and environmental conditions, yet traditional methods struggle to forecast fermentation outcomes proactively. Built on multi-dimensional data from 140 academic papers, this platform leverages advanced tree-based models (XGBoost, CatBoost, etc.) to deliver precise predictions of key fermentation quality indicators—including pH, ammoniacal nitrogen, lactic acid, acetic acid content, and nutritional component retention rates—at the stabilization stage. Simply input raw material nutrients (e.g., crude protein, water soluble carbohydrates), process parameters (e.g., inoculant dosage, chopping length, density), and environmental factors (e.g., temperature, altitude) at the silage initiation stage (Day 0), and the platform will unlock insights into fermentation tiers. Equipped with model interpretation technologies, it also reveals core influencing factors and their optimal regulation ranges, providing data support to optimize fermentation processes, enhance feed quality for livestock production, boost biogas generation, and improve ethanol yield for downstream applications.